Firstly, what is a Steam Turbine:

A Steam Turbine is a device that converts potential energy of high pressure, high temperature steam into Kinetic energy. This Kinetic energy is supplied to the rotary blade where it is transformed into mechanical energy. This mechanical energy is used to drive rotating equipment like pumps, compressors, fans etc.

A Steam Turbine is powered by the energy in hot gaseous steam, it has spinning blades that turn when steam blows past them. The power in a steam turbine is obtained by the rate of change in momentum of a high velocity of steam impinging on a curved blade which is free to rotate.

Challenges with Steam Turbines:

Due to the environment around Steam Turbines water contamination in Turbine lube oil is a serious concern. Thrust bearings and trip components on the governor end are vulnerable to even slight water content in the lubricant.

Process steam turbines present a unique challenge for bearing protection. As the carbon rings containing the steam wear, high temperature, high velocity steam travels down the shaft directly at the bearing seal.

Instead of conventional flow-through Labyrinth baffles, AESSEAL have designed the Labtecta ST which unlike some of our competitors also incorporates the vapour block system.

Solution to the challenge:

AESSEAL has developed Labtecta TM designs specifically designed for Steam Turbine applications, This design features:

- High temperature Static shaft seal

- Steam deflector/flinger

- Aflas ‘O’-rings as standard

- Internal shut off valve

- Extra clearances for thermal expansion

Due to AESSEAL’s vast data base, the most commonly found Steam Turbine (Coppus/Elliot/etc) designs already have Labtecta designs drawn and in circulation working on various sites around the globe.

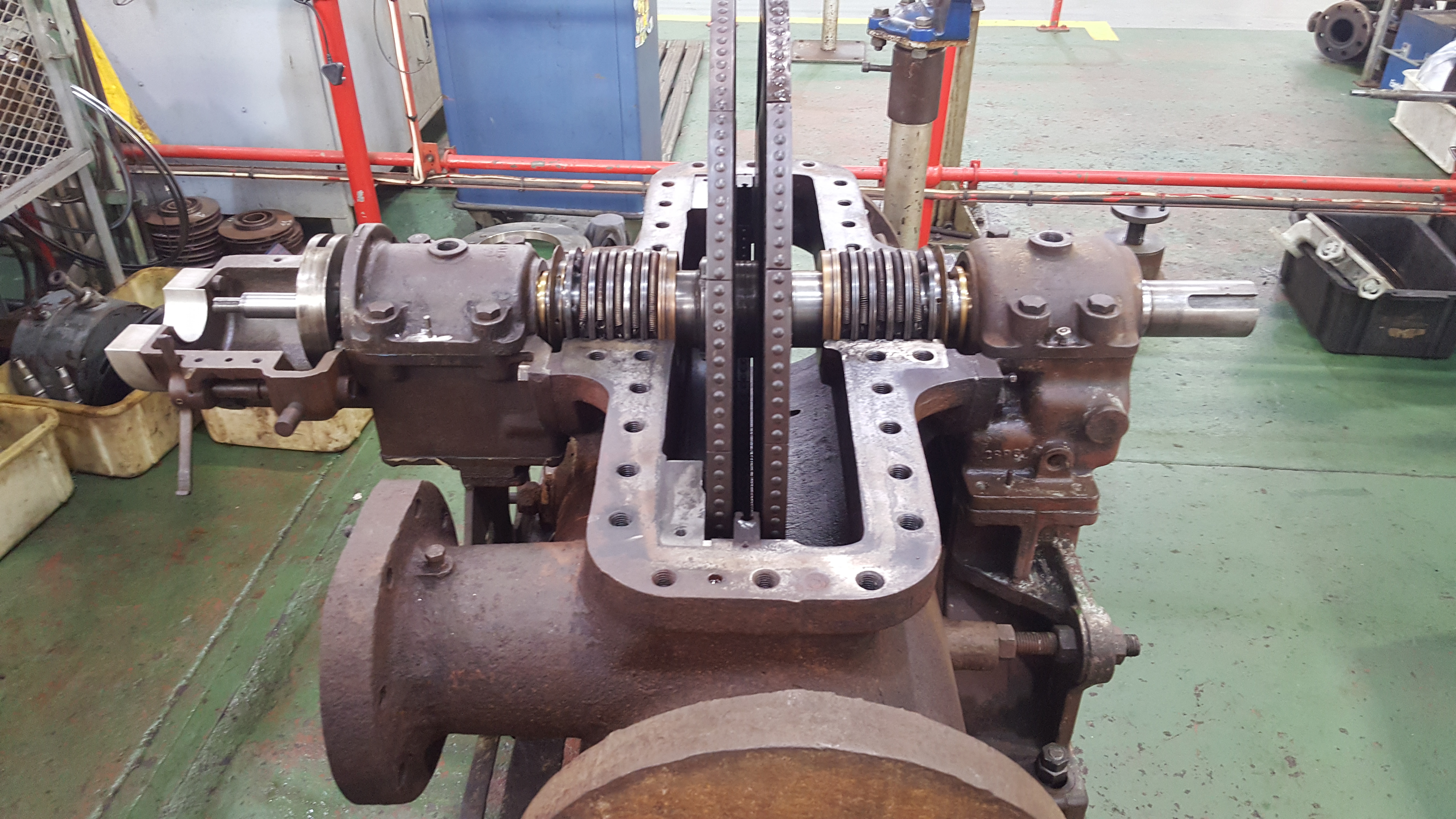

GA of Labtecta ST for a Worthington S2R Class III Turbine

One of the largest Oil refineries in South Africa have standardised with the Labtecta ST design, Before AESSEAL presenting our version to them they were using a competitor version, One of the reasons for the change to the AESSEAL design was our ease of installation as the competitor version had to be heated up on an Induction heater, then quickly slid onto the shaft into the correct position, if not in correct position the Isolator had to be tapped to get it correct. AESSEAL ST design has Aflas ‘O’ rings for ease of installation incorporating a Steam deflector made of Graphoil packing which is held in position by a S/Steel circlip which is easily removed for ease of installing the Labtecta into correct position.

AESSEAL version Bearing protectors are designed to suite your application and very rarely need mods to be done on the equipment, AESSEAL prefer to keep OEM equipment to a standard and therefore design our solutions to fit into your standard equipment.

Close up of installed Labtecta ST on Turbine.